Maintenance Servicing

OVER 4 HOURS OF WATCH REPAIR LESSONS

Level 1 of the Watch Repair Course provides more than 4 hours of teaching with 41 full high definition videos, plus access to our bonus videos specific to level 2 as well as full access to our back catalog of watch repair videos.

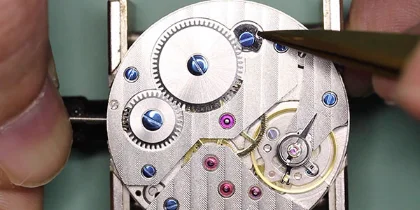

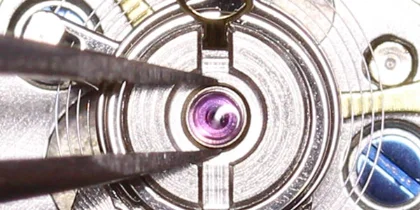

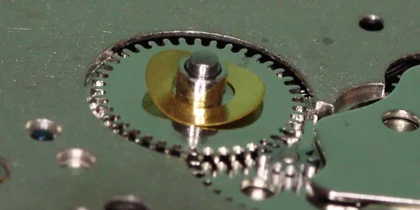

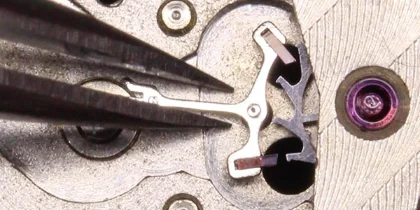

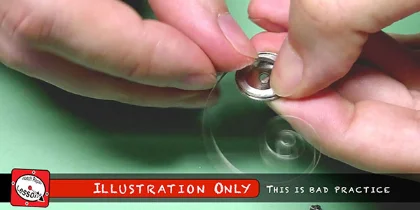

All the images you find below, and on this whole web page are actual screen shots from the lesson videos. Once you have gained access to the course level, you will have access to it for as long as you need – there are no time limits. This will allow you to go over and review all the course content as many times as you like, even after you have completed the course.

Get Instant Access

Level 2 – Maintenance Servicing

- Enrollment Cost

Each lesson and topic is presented to you in full high definition 1080p video. There is a lot to learn and so we have ensured that there are no time limits, you can pause your learning and pick up from where you left off at any time in the future. And you have instant access to the course once you have enrolled.

- COURSE ACCESSYou get immediate access to the course material including the HD resolution video lessons and no time limits.

- NO LIMITSYou can review all the material, including the videos, as many times as you wish.

- COURSE EXPIRATIONAccess to this course does not expire!

Get this course level even cheaper - its included in our...

Getting Started Bundle

What you will learn in Level 2

HOW TO SAFELY STRIP A WATCH MOVEMENT TO PIECES - AND RE-ASSEMBLE IT

Level 2 Course Content

c2.0.0 Introduction

This video lesson serves as an introduction and summarizes the teachings provided in level 2 of the Watch Repair Course.

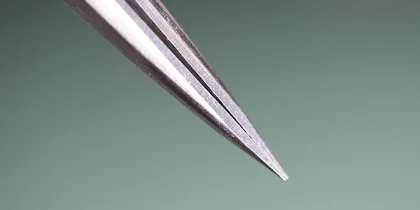

c2.0.1 Using & Maintaining Tweezers

In order to reduce the risk of watch parts getting lost, it is advisable to choose high quality tweezers and to maintain the tweezer tips. When new to watch repair you should spend quite a bit of time practicing with your tweezers and developing your technique.

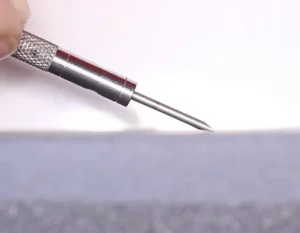

c2.0.2 Using & Maintaining Screwdrivers

c2.1.0 Stripping Down The Movement

There are no specific rules to the order a watch is stripped to pieces. We discuss the importance of being aware of the potential to cause damage being greater unless you follow a basic guideline procedure.

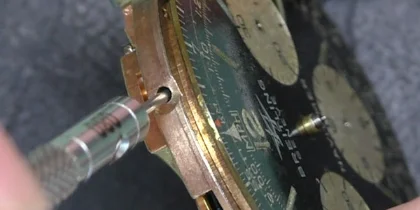

c2.1.1 Removing The Movement From The Watch Case

It is never a good idea to start stripping a watch movement down when it is still in it’s watch case. The movement may not be fully secure and you will run the risk of damaging the dial as you apply downwards pressure on certain screws. This lesson discusses the same removal of the watch movement from the watch case.

c2.1.2 Removing The Dial and Hands

c2.1.3 Removing Power From The Mainspring

c2.1.4 Removing The Balance

c2.1.5 Removing The Motion Work

Removing the Motion Work before removing the Train Wheels is a great example of where observing this guideline is important because the Cannon Pinion is friction fitted to the Centre Wheel.

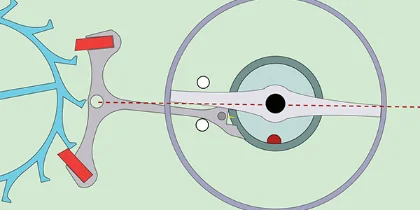

c2.1.6 Removing The Pallets

The Pallet fork is located under the balance and is secured with a bridge which needs to be removed first. The pallet staff pivots are very fine and if you are not careful when removing the Pallets then you run a real risk of them breaking.

c2.2.0 Inspecting The Watch Parts

Watches are designed to run for a very long time, sometimes many years, without the need for service. However, some watch owners will tend to have an “if its’s not broken then it doesn’t need repair” attitude towards their timepiece. We discuss the importance that you inspect each part individually as you strip and service a watch movement.

c2.2.1 Inspecting Jewels And Pivot Holes

c2.2.2 Checking For and Dealing With Rust

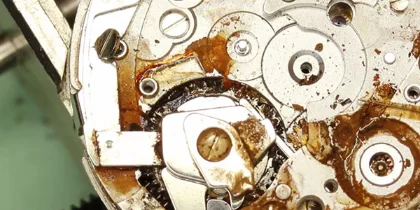

Rust is most definitely an issue you will come across at some point when you start servicing and maintaining watch movements.

c2.2.3 Checking For Damage and Wear

c2.3.0 Cleaning Techniques

c2.3.1 Cleaning By Hand

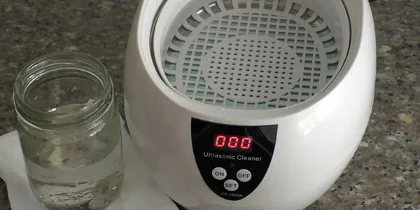

When you are first starting out with watch repair, it may not be practical or even advisable to invest in expensive equipment such as ultrasonic machines or watch cleaning machines.

c2.3.2 Using An Ultrasonic Bath

c2.3.3 Watch Cleaning Machine

Using a dedicated watch cleaning machine will both increase your productivity and arguably give you better results when cleaning watch components. You will still need to be able to clean certain parts by hand, but investing in a watch cleaning machine will be a natural step forward as you progress in watch repair.

c2.4.0 Lubrication And Re-Assembly

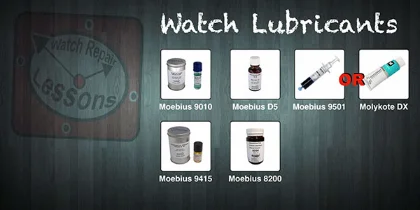

c2.4.1 Choosing Correct Lubricant

Many modern watch movement calibers will have a corresponding data sheet with part numbers, illustrations and often an oiling chart. These can be extremely useful to help you determine the correct lubricant for a particular friction point.

c2.4.2 Lubrication Techniques

Before we get started with re-assembly, lets take a look at some principles in the lubrication of friction points in mechanical watch movements. For the most part, you will need to lubricate where any two components come into contact and interact with each other…

c2.4.3 Re-Assembling The Watch Movement

Now we are ready to start re-assembling and lubricating the movement. You may remember, we previously talked about a guideline procedure for stripping a movement to pieces.

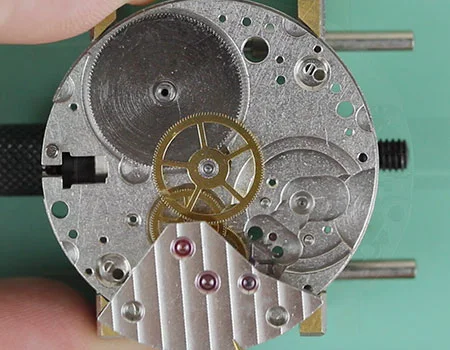

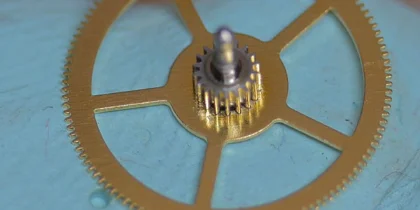

c2.4.4 Assemble The Train of Wheels

If you made notes or took photographs whilst you were stripping the movement down, this should be a relatively simple task. Assembling the train of wheels is a simple case of placing the wheels the correct way up and in the correct order.

c2.4.5 Assemble The Going Barrel

When re-assembling the barrel you have to make a choice wether to use the existing mainspring which you removed when you stripped the watch down, or to replace it with a new one.

c2.4.6 Using A Mainspring Winder

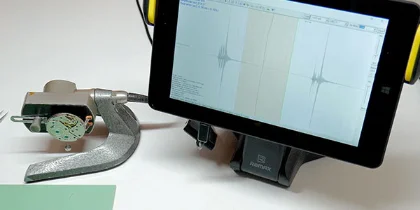

c2.5.0 Testing & Timing

c2.5.1 De-Magnetising The Movement

c2.5.2 The basics of regulating a movement

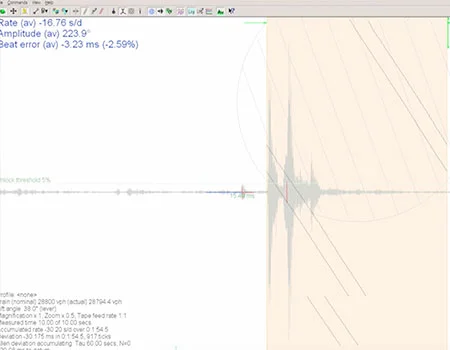

If a watch does not maintain a reasonable expectation of time-keeping, then it’s does not serve much of a purpose. And of course, following a full strip down and re-assembly along with fresh lubrication applied and perhaps even replacement of worn parts, the time keeping of the movement will need to be assessed and adjusted accordingly.

c2.5.3 Adjusting The Movement Rate

c2.5.4 Setting The Movement In Beat

As the balance oscillates, it interacts with the pallet fork twice. These are called vibrations, or beats. Effectively it is the ‘tictoc’ sound you hear with any mechanical watch movement.

c2.5.5 Adjusting For Positional Error

c2.5.6 Testing a Movement

Now that you have adjusted the rate of your watch movement, it is very important to put the watch through various stages of testing.

c2.6.0 Summary

This video lesson follows the level assessment and summarizes Level 2 of the watch repair course.

Recent Reviews For Level 2

Detailed and accurate

Excelente course. Very clear and easy to follow.

Level 2

Mark i have really enjoyed this course and it as helped me a lot my skills are improving every day thanks to your lesson and i am looking forward to…

Level 2

Love the course content. I can’t wait until I get my 6497 movement so I can start working on it, as we progress through the program.