Mechanical watches are amazing pieces of machinery. We expect a lot from them. They are expected to be wound up every day – they are expected to work 24 hours a day, 7 days a week and all through the year. Most people will spend a fortune on their cars which at most may run for an average of a few hours a day (sales reps excluded). But the watch only usually get serviced when things go wrong. I mean… if it ain’t broke, why fix it huh?

Well actually a watch has many moving parts and to get the best out of your watch it is just as essential to regularly have your watch serviced as it is your car. It is recommended that a mechanical watch has a service at least every three years. The oil degrades. Small particles of dirt entering a watch over time. Metal particles from wear and tear, these particles over time will contaminate the old oil and turn it from a lubricant into an abrasive.

The correct grade of oil (or grease for some components) needs to be used. We have several grades which we use on various parts of the watch. Typically we will use three types of oil and a grease in most watches serviced. Some watches (e.g. ETA 7750 chronograph) will even require extremely specialised and expensive oil for certain friction parts.

Then there is the amount of oil used. Too little and it will run dry very quickly. Too much and the oil could spread to places you do not want it to be. For example, if oil contaminates the hairspring of a watch then that watch is very likely to gain time at a very high rate.

The watch taken apart in the image above is a prime example of over-oiling. In fact it is a sure case of over-oiling with the wrong type of oil.

Using the wrong kind of oil and even worse, in the wrong places will be extremely detrimental to the running of the watch and ultimately will cause the watch to stop.

This is an incredibly high amount of oil which, by the way, is way too thick and has caused a lot of drag on one of the calendar mechanism wheels. A small amount oil in the jewel hole would have been enough. Any kind of drag in a watch will cause problems and so this is completely unacceptable.

Opening the mainspring barrel and we have way too much grease which was applied. This has turned black caused by tiny metal fragments rubbing off the softer metal of the barrel casing mixing with the grease. This tells us that not only was this too much lubrication, but the watch may not have been serviced in a long time.

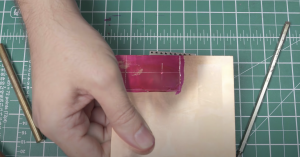

Each component is cleaned with special chemicals and using ultrasonic technology which cleans the parts to a microscopic level. The image above shows the watch after cleaning. You may possibly notice that this was a self winding (automatic) watch. The oscillating weight (top left) was also damaged in this watch, a new bearing has been ordered.

Now we assemble the watch. Each part is examined under 20x magnification for damage or wear. As we go along, a correct oiling regime is applied.

It is also important to remove the Incabloc end stones. You may see the gold coloured spring clips which we undo to be able to remove the endstone and jewel hole.

A correct amount of oil is placed on the end stone before re-assembly.