This was a challenging, yet enjoyable project.

As found in my previous post regarding this watch, the watch had a damaged balance staff, a broken jewel and the hairspring was quite out of shape.

In fact – on further examination I found the balance staff was actually non-hardened and so the metal was very soft. When turning off the rivet it almost felt like cutting brass.

I found a suitable jewel for the fouth wheel pivot size and as this was a rub-over style jewel I had to use some antique jewelling tools to prepare the fitting. Once fitted and rubbed in – the wheels are placed back in the watch to test the freedom of the wheels and the tru-ness. All was satisfactory so I dismantled the watch again for a deep clean.

After cleaning all the components next next job is to tackle the hairspring. This is a slow, methodical job. The idea is to get the coils as even as possible. This spring had around 15 irregular bends in it which had to be identified and rectified.

The broken jewel needed to be replaced – and for this I use the best quality “Seitz” jewels. First I have to measure the pivot on the fourth wheel to make sure I select the correct diameter. For this I use a pivot gauge and what I want is to place the wheel pivot in the correct size hole in order to ascertain the correct diameter.

This watch has rub-in style jewels. It is tempting to ream this out and use the more modern press-in method f fitting the jewel. However, best practice over-rules this and we should attempt original methods where possible. So I have selected an antique jewling tool to spread the metal to allow the new jewel to be pressed into the seating. Once it is placed correctly – another tool is used to close the metal over the jewel – the jewel is secure and tight in it’s seating.

Now to make the balance staff – first I have to safely remove the old one without damaging the balance wheel. The best way to do this is to mount the balance on the lathe and carefully cut away the rivet. Once this was done I found the staff was still tight on the wheel so I used a tool called a Platax tool to safely knock the staff out. This tool secures the balance wheel and makes it very difficult to damage the wheel or the hole at the centre.

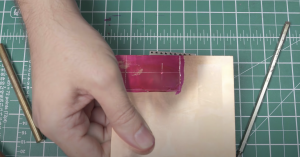

When I cut a new staff, I always make the pivots over size in both diameter and length so that I can slowly reduce them to the perfect size. At this stage it is more about eye and feel. The tool I use is called a Jacot tool. I use a burnisher to reduce the pivots and this has the added bonus of further hardening the metal surface.