These are lovely old watches. Made from 9ct gold which is quite soft, many will wear around the edges. This particular one I was working on today had a gaping hole on two corners.

Now servicing a watch like this on a regular basis is a must but there is no point in spending the time cleaning each part and oiling it when it is only going to get dirty again very quickly due to the holes in the case. So I had to deal with it.

See the before and after shot:

As you can see – its a great looking vintage watch. The movement was in good condition but the crown was worn and (you cant see this) the pendant sleeve was broken. I had to make one as these are very hard to come by now.

Here is a close up of the case damage (or wear).

The problem being that this allows dust and skin to enter the watch quite easily – this will contaminate the oil and affect timekeeping. Hairs and fibres can enter the watch and wrap around the wheels causing the watch to stop.

As you can see – this is a lovely 21 jewel movement from Waltham, most likely from around the 1920 – 1930 area. A bit messy (well due a service) but in working order.

The movement stripped down. I will clean each part in an ultrasonic watch cleaning machine before re-assembly, oiling and regulating.

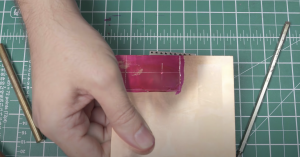

I needed to fill that hole so I flattened a piece of 9ct wire and placed it in the hole with as little gap as possible. I then ran 9ct solder through it to secure the wire in place and strengthen the surrounding area. I will remove the excess wire and file/sand the area to shape – then ready for a good polish.

Its starting to take shape – needs a good polish. The other corner is also done.

Now I have polished and cleaned the case. Looks good doesn’t it? Now I have to finish the movement.

Things are going well – not too much wear and the train of wheels are running true. Here you can see me replacing the barrel bridge.

Now to regulate the watch – first we need to wind it up. I use a special tool for winding a watch like this when it is not mounted in the case so as not to cause damage.

And we’re done! Just need a strap to finish off. I love the look of this watch – nice and clean, easy to read dial. Not too big. Fantastic!